GAC Toyota Motor Co., Ltd.

Selection time in procurement of emergency maintenance parts reduced by 70%!

Customer profile

GAC Toyota Motor Co., Ltd., a joint venture between Guangzhou Automobile Group Co., Ltd. and Toyota Motor Corporation, outsources dies and molds, but the maintenance during production is performed in-house.

Conventional maintenance and repair procedures of dies and molds

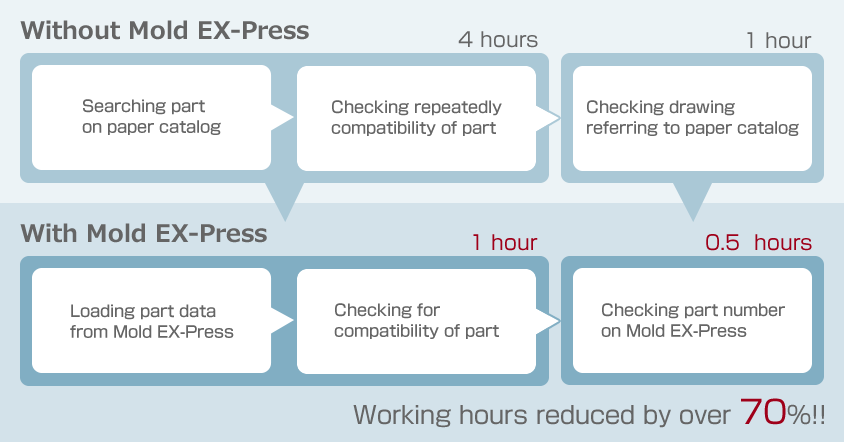

Dies and molds are maintained periodically to ensure a high quality. For replacement parts, engineers searched in the Misumi catalog, and checked whether the requirements were met. Additionally, CAD drawings had to be checked constantly to the matching ones in the Misumi paper catalog.

Troubles in the maintenance

Quick repair or maintenance is critical, so that production can be resumed promptly. When a part broke down, a replacement was sought in the Misumi catalog in order to save time. Still, it sometimes took up to half a day to check whether the selected part met the requirements. Considering this process for several damaged items, reducing the time for this task was crucial.

How was the maintenance process changed?

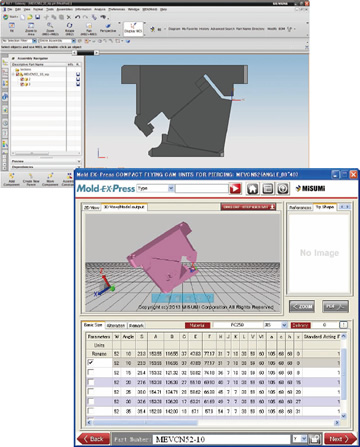

Mold EX-Press allows direct output to 3D models and 2D. It enables quick search, 3D preview and immediate dimension selection, of the checking process, significantly improving efficiency.

Results of introduction

Since the introduction of Mold EX-Press, a replacement part can be selected in just one hour. Furthermore, it now takes only thirty minutes to confirm the drawing.

Voice of the customer

Designers say: “Mold EX-Press is more sensible and convenient than the paper catalog”, “Parts can be checked on 3D models, saving time”

and “The paper catalog is no longer necessary for checking the CAD drawing”.

Over 50,000 customers

are currently using

Mold EX-Press.