Tata Motors Limited

Design process time reduced by 50%.

Customer profile

Tata Motors Ltd. is an Indian car manufacturer based in Mumbai, and a subsidiary of the Tata Group. It is the world's 18th largest motor vehicle manufacturing company.

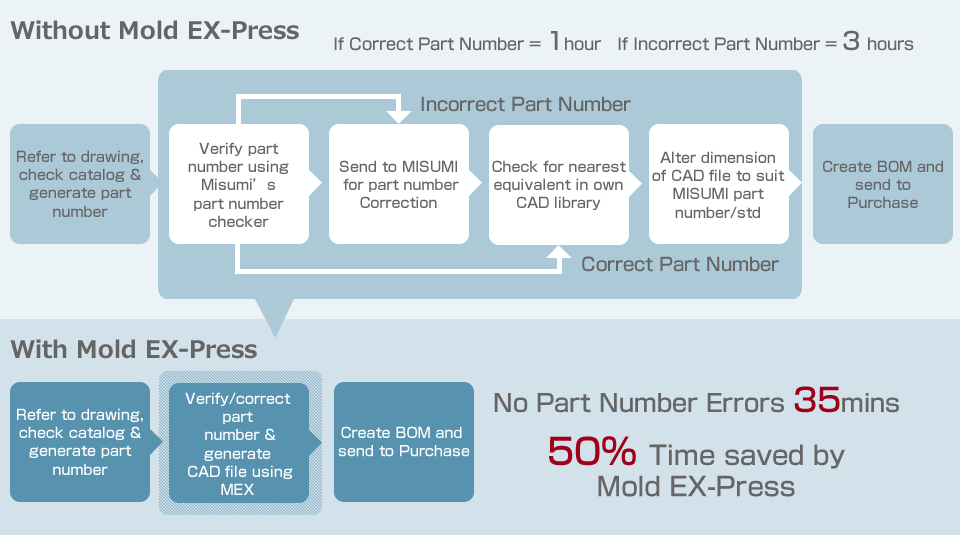

Conventional design procedures

Prior to the installation of Mold EX-Press, designers would go through the following steps:

- Check the Misumi Paper catalog for the required part and generate a part number.

- Using Misumi’s online Part Number Checker, the designer would verify the part number.

- The designer would then create a 3D drawing, using the nearest equivalent part file from Tata’s own CAD library, and alter the dimensions to Misumi Standards.

- The part number would be added to the BOM, and sent to the Purchase Dept.

If Misumi’s online Part Number Checker could not confirm the part number, the process took even longer.

Troubles in the design process

Before Mold EX-Press, the process required four different data sources:

- Misumi Paper Catalog

- Misumi Part Number Checker

- TML CAD Library

- Manual entry in TML BOM

Part number conversions or BOM creation phase were prone to errors. Also, most parts were re-drawn, leading possibly to further errors.

How was the design process changed?

Mold EX-Press generates and verifies part numbers, and creates accurate part drawings and a BOM through one single source. Furthermore, part numbers filled in the TML BOM are exported from Mold EX-Press, eliminating possible part number errors.

Results of introduction

In the time previously required to generate and verify a part number, we can now additionally

- Create a CAD drawing

- Generate a BOM

Mold EX-Press has reduced our design process time by approximately 50%.

Voice of the customer

According to customers, Mold EX-Press’s biggest advantage is that it simplifies and speeds up the process. “Mold EX-Press generates and verifies part numbers, and creates CAD drawings and BOMs from one single source”.

Over 50,000 customers

are currently using

Mold EX-Press.